Floor Construction Details

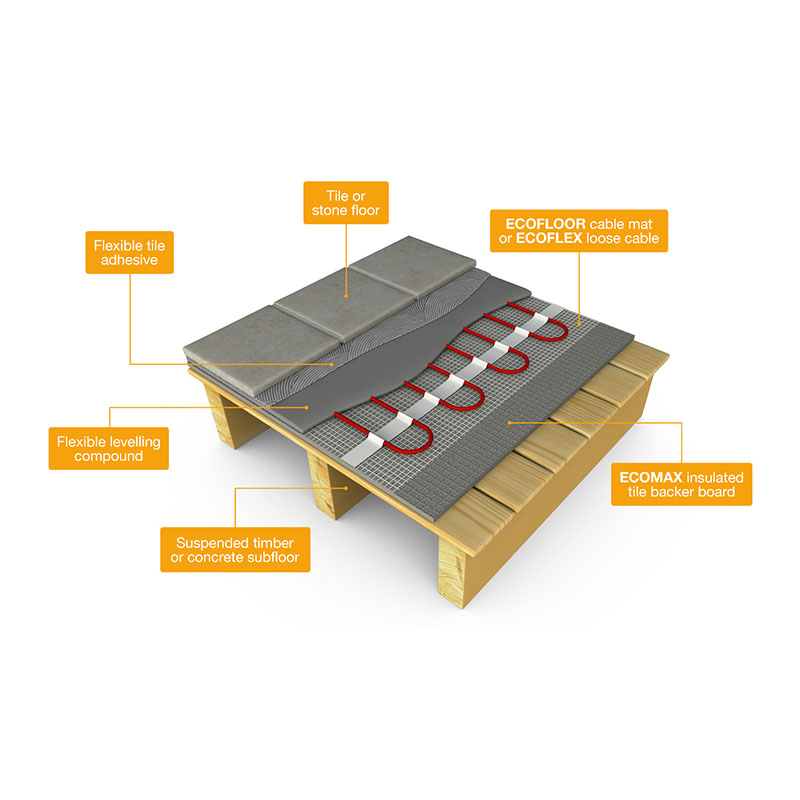

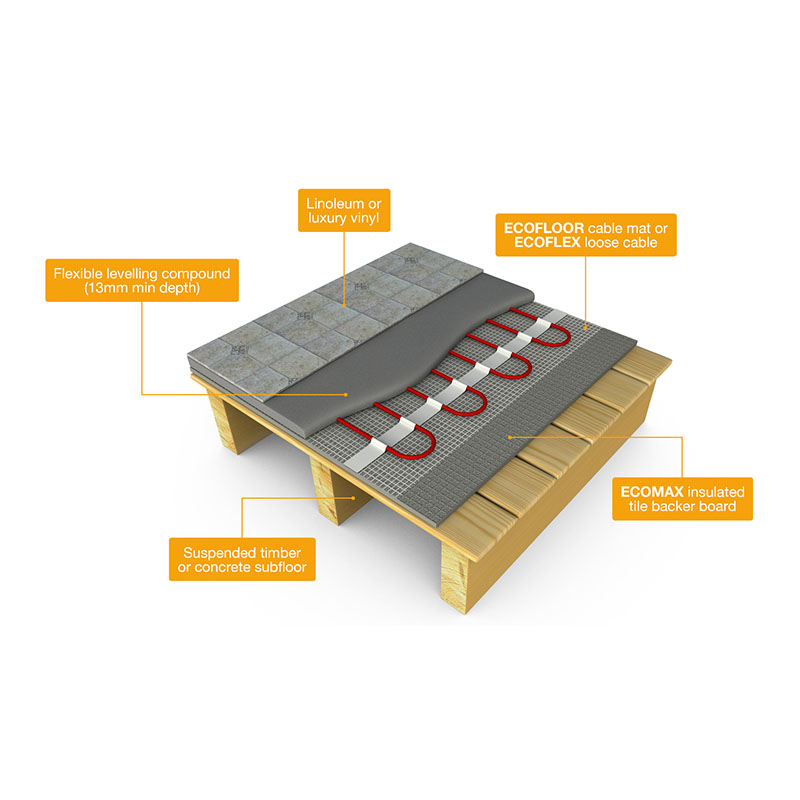

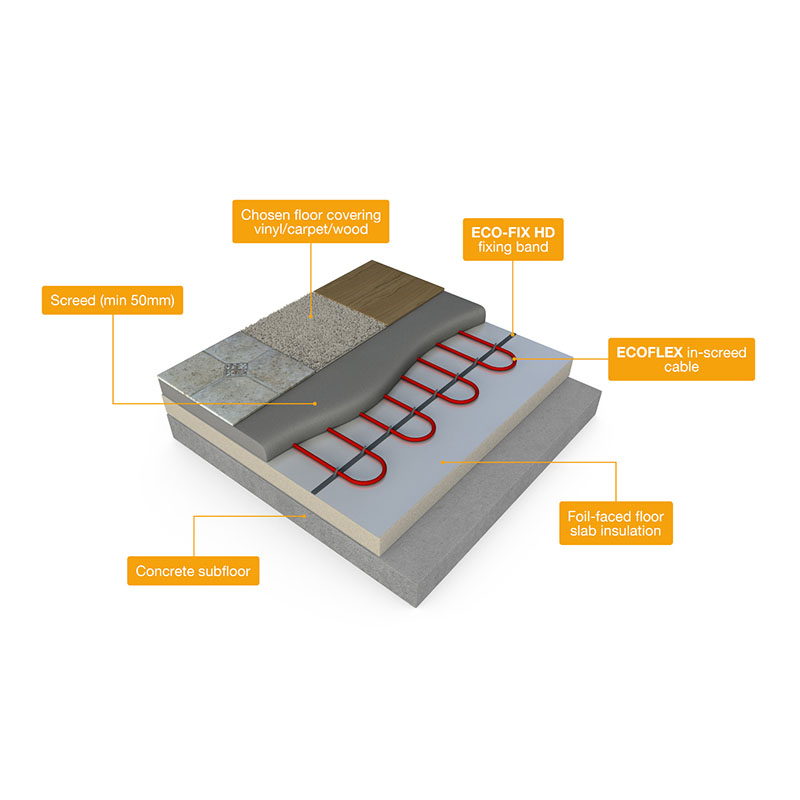

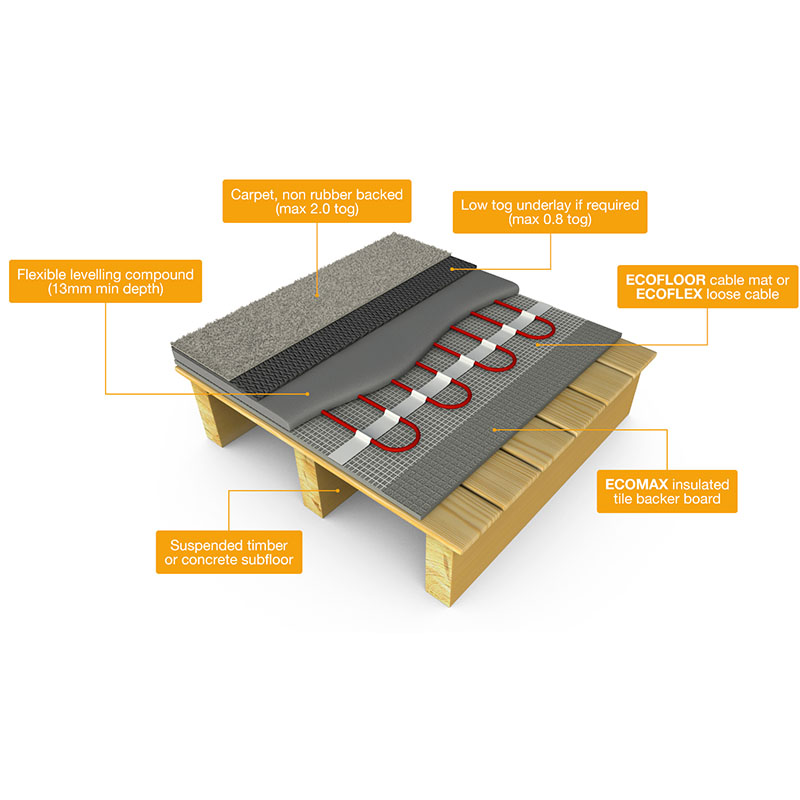

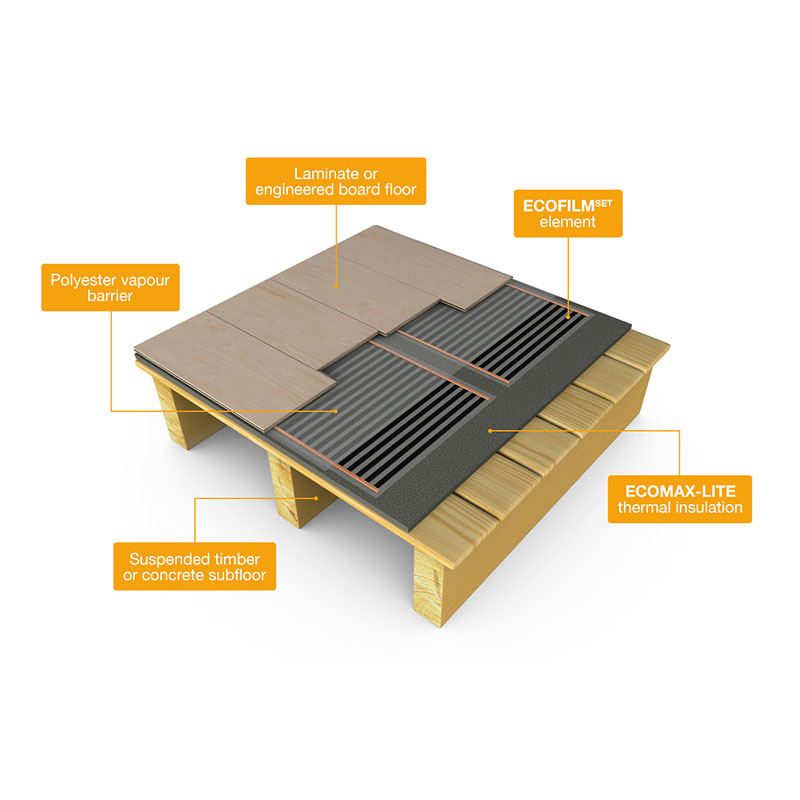

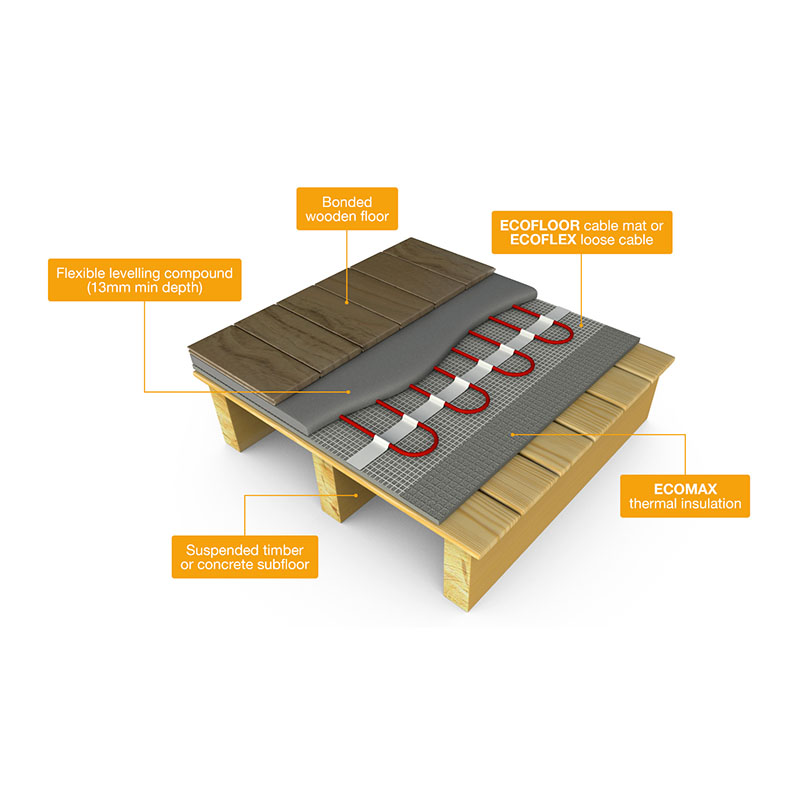

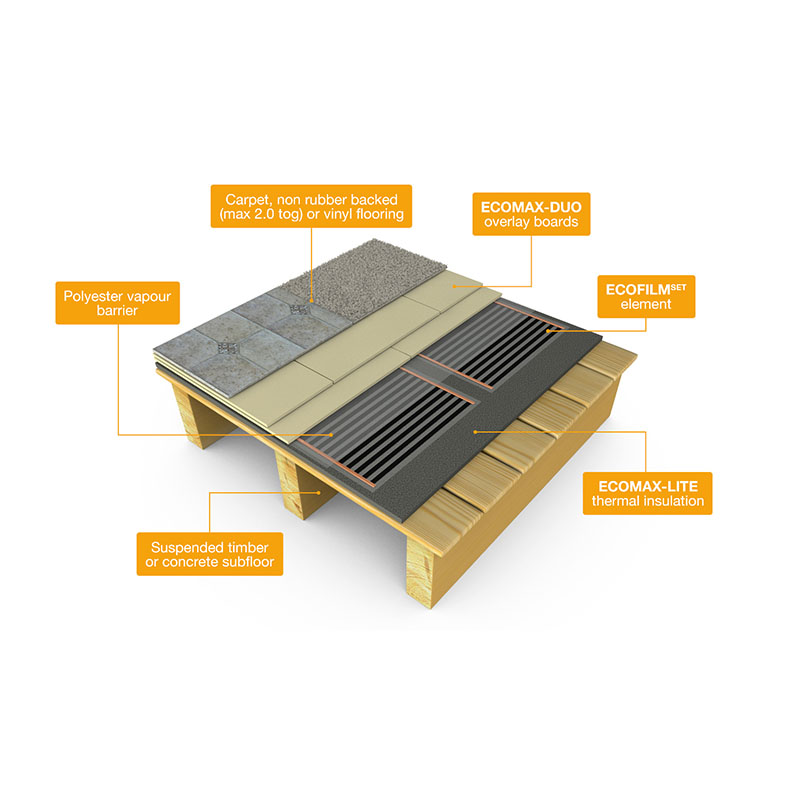

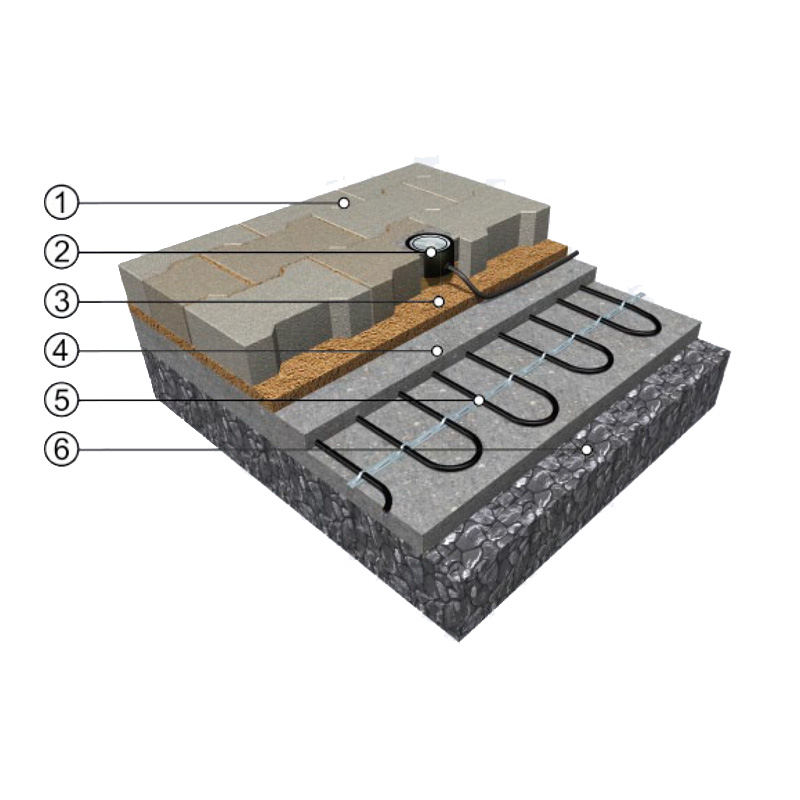

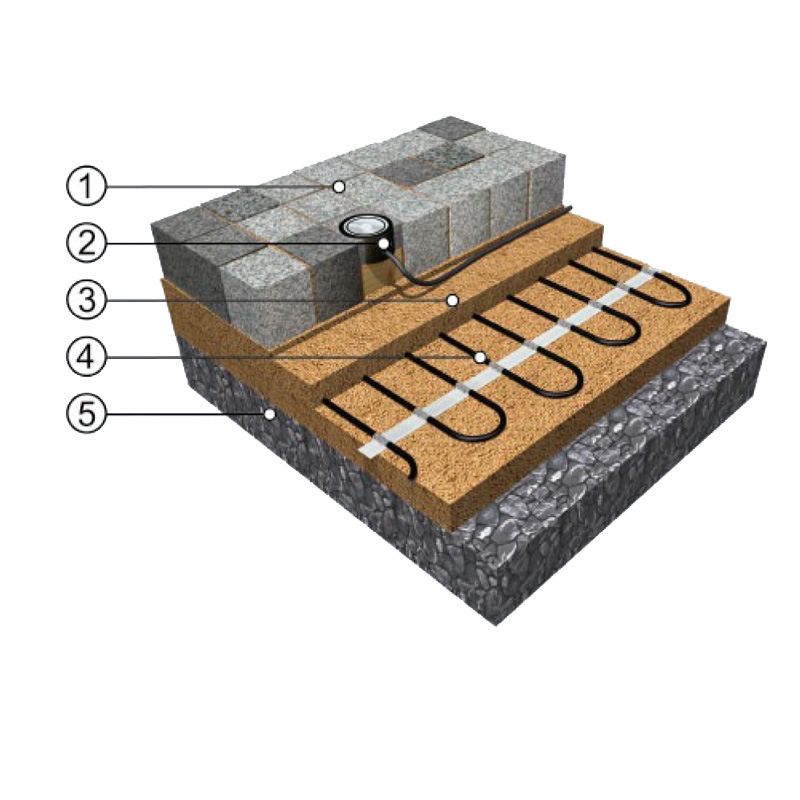

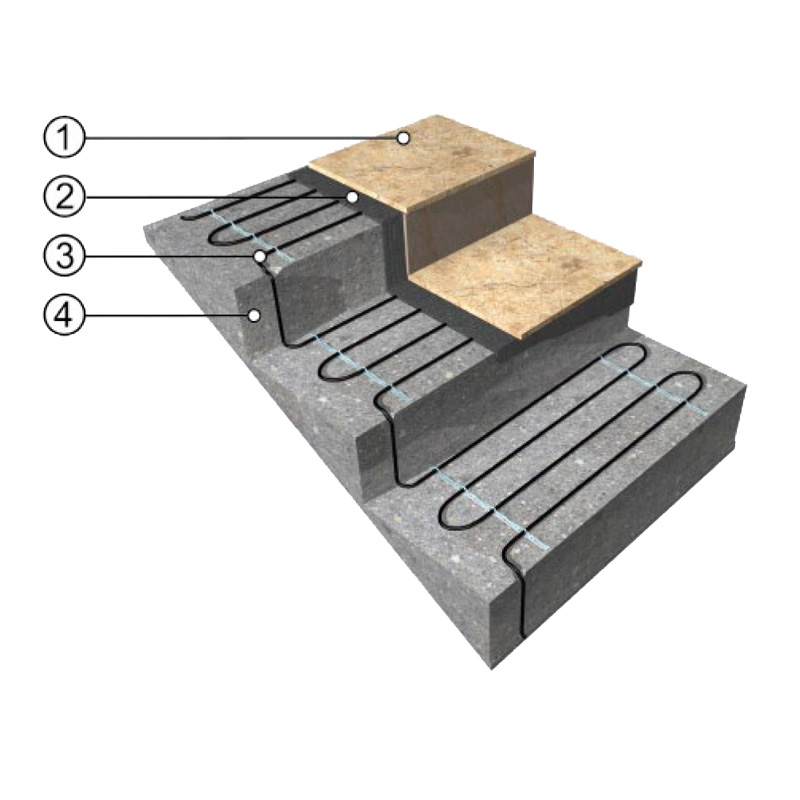

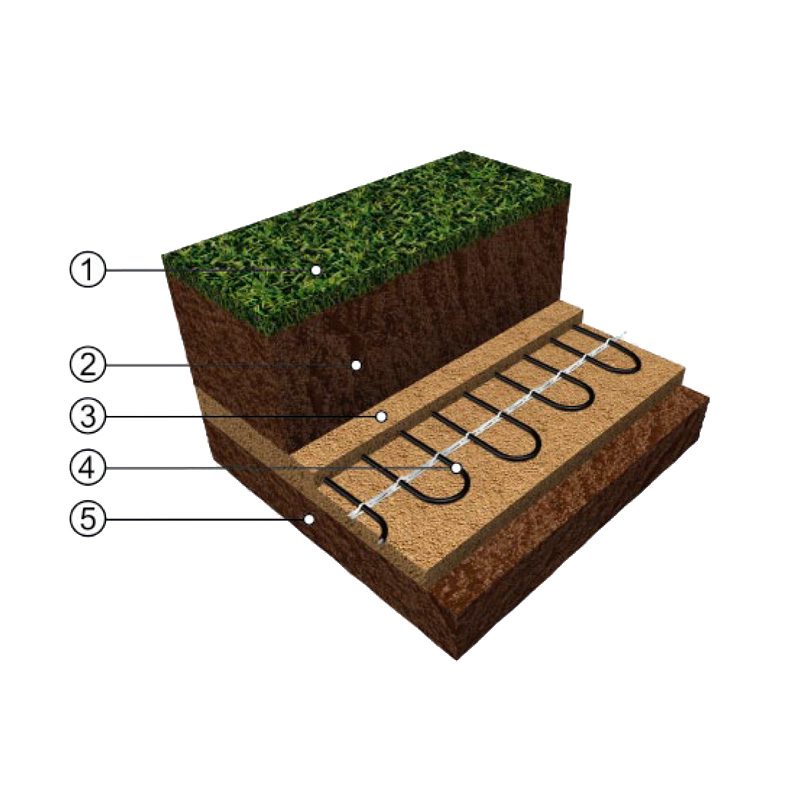

It is important to choose the correct underfloor heating product dependant on your subfloor material and your chosen floor covering.

The following underfloor heating constructional details will show you the floor build-up for the most popular types of finished floor coverings.

On some occasions you may have a choice of product and floor construction to achieve your choice of heated floor surface. The final product decision may depend on a comparison of factors such as: finished floor build-up height, speed or ease of installation or cost. Whatever product or construction method you choose, you can be sure that it is well proven and will provide an excellent heating system.

Insulation materials are a crucial component in all the construction details shown. Use of the recommended insulation material will enable the floor to heat up faster and run more efficiently.